Try moving the piston horizontally

Was thinking about doing a gas through Etek as a fun winter project and that got me thinking about something else.

Completely custom reg/asa a la Empire Relay but with the features I love of the POPS from PE. No idea if this would even work, just drew it up at work.

From left to right (terrible phone picture, sorry)

Might draw this up in Inventor, but I have a feeling it'd be huge.

Dark outline: Body (similar to how it is now)

Light gray: End cap w/Adjuster

Cross hatch: Main Reg body

Pink: Base seal

Gold: Spring

Pink II: Piston

Pink III: Tank Pin push rod

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly

Try moving the piston horizontally

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly

You are very sensitive to HP input there.

Edit: my suggestion, run some real numbers for the required spring stack to get any real pressure drop.

Last edited by PBSteve; 10-17-2013 at 09:57 AM.

Ever so many citizens of this republic think they ought to believe that the Universe is a monarchy, and therefore they are always at odds with the republic. -Alan Watts

I work for the company building the Paragon

A few of us have experimented with regs inline like this, we found that unless you make it longer so you can get the flow you need it's not feasible. A few people (J4 is doing this too) have flipped the piston up and down to fit in the same form factor, then you can adjust it from the under the asa.

1279050_655700267796554_167944895_o.jpg

Thanks for the input. I figured it'd be a decent amount larger than the standard POPS reg. I don't have much experience with regs/reg design so I went with what was the simplest design I could come up with (for the reg part at least)

I"ll have to draw it up to get an idea of size and to get some idea of what I could expect for spring stack to get a pressure drop.

The bottom adjustment looks promising thanks for the info.

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly

Sounds like a interesting project. I would be interested to see some calculations done on something like this. Would you want this to be like an LPR or an HPR?

So I'm thinking that the Rap4 AG1 design/parts may be good for this. Anyone know how the recharge rate is on them?

From what I can figure out the AG1 reg portion is 1/2" long, the POPS section I'd use is .8625" long, and the ASA section would be .625" long.

Total length would be about 2" long (if what I figure is correct) which is slightly longer than the existing POPS body which is great.

I'm thinking that the gauge could be swapped for a fitting/air transfer port and the standard ASA end would be removed.

Here's the AG1 parts list for reference:

Last edited by skibbo; 10-19-2013 at 09:51 AM.

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly

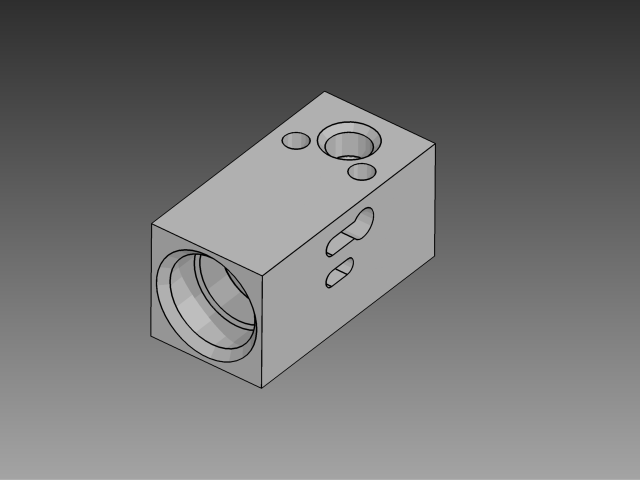

Really blocky start, just wanted to see how things would fit together. I'm thinking a rail of some sort is a must, although this is the way I have my OOPS set up as gas through and it works pretty well. There are 2 counter bore holes on the bottom to allow the use of socket head screws to hold everything tight.

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly