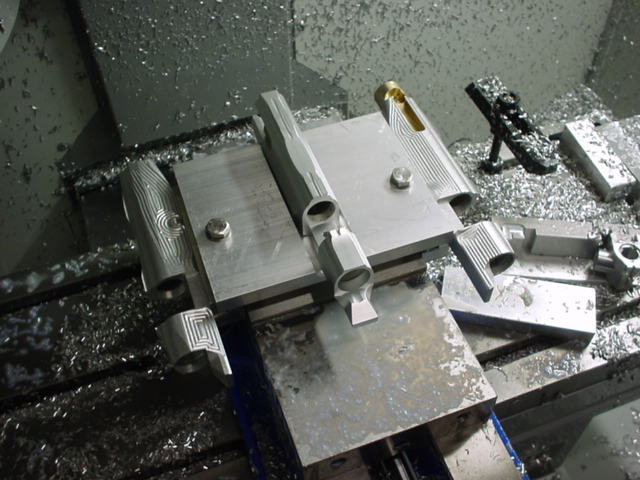

I recently acquired a prototype version of the Aztec X-mag and wanted to see what you guys think about an idea I have. I only have the body and a blank feedtube. I did not get any of the milled battery housings. (see below)

My idea: I have been toying around with the idea of completing the prototype and finishing it with a proper anodizing. I really like the design and think it would be awesome to see it put together.

Should I leave the prototype as is, with just the milled body, blank module, sitting on an e-mag frame? Keeping it raw.

or

Should I finish it, mill a new battery pack, module, and get it anodized in a solid color?

If I decided to finish the prototype my next problem would be to find someone who could actually help me mill the parts. Since I'm no machinist/expert/etc I have no clue how this is done. My assumption would be to find the "G-code" for it. I spoke with John about the code, but since it is specific to his machine and tooling I couldn't just copy and paste his file and give it to someone to reproduce. John also mentioned things like toolslot8 ,12mm ball end-mill, featurecam, Tebis, but it all went over my head. Maybe Simon can chime in and explain

Do you guys think this could be easily produced or recreated?

I figured this would be a good place to start. I would love to see what you guys think of this.

-Rob

Do you guys think this could be easily produced or recreated?

Do you guys think this could be easily produced or recreated?

Reply With Quote

Reply With Quote

I'd love to see it build into a full gun and anodized. Maybe a gold colour to go with the Aztec theme?

I'd love to see it build into a full gun and anodized. Maybe a gold colour to go with the Aztec theme? I posted the only pictures I could find of the Aztec and it doesn't look like the vert module was milled. One of my ideas was to get the module (both vert and warp) finished as well. When you have the module sitting on the body, it just screams out "mill me" I'll try and get some pictures tonight to visualize.

I posted the only pictures I could find of the Aztec and it doesn't look like the vert module was milled. One of my ideas was to get the module (both vert and warp) finished as well. When you have the module sitting on the body, it just screams out "mill me" I'll try and get some pictures tonight to visualize. so John Sosta stole it and put it on his personal Xmag.

so John Sosta stole it and put it on his personal Xmag.