No idea, sorry.

Oh absolutely, I don't have a TPX to hack up though haha

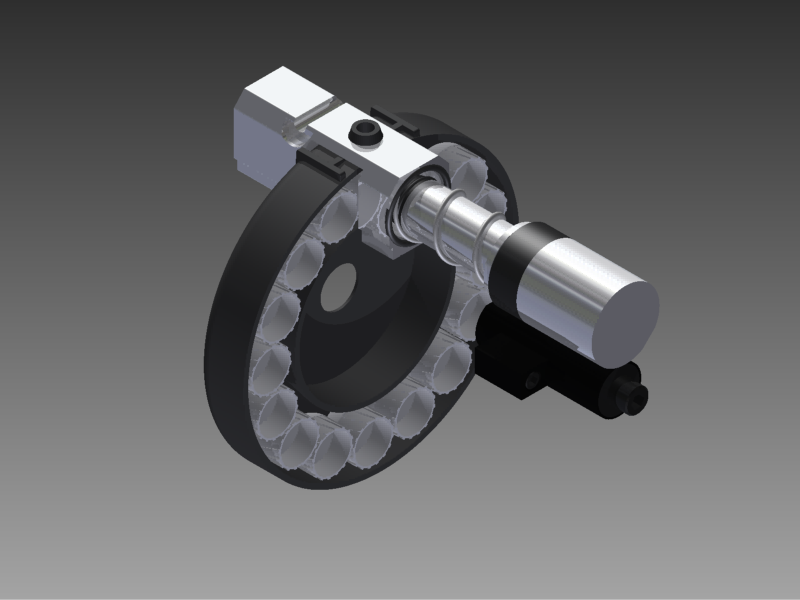

Got some more work on the CAD end done. Did the important dimensions, didn't do valve/regulator internals since they won't change.

Also, the bolt WILL fit through the hole in the mag, tested it out with the parts I have and I think that'll work great. So far the only thing changing would be the breach block, but that's expected.

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly

Haha. Me too.

The issue I'm having is re-routing the air lines while trying to use the existing parts as much as possible. At a minimum the Regulator will need to have the short gas line port (between reg and firing valve) moved 90* so that the protrusion on the side of the reg is sticking out towards the bottom. I'm trying to figure out the easiest way to attach a C02 piercer to the reg but having the o-ringed tube fittings instead of threaded is making it a bit more complicated than I wanted.

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly

So as I mentioned, rerouting the gas line has been giving me a bit of trouble.

I came up with two options:

OPTION 1 "I'D TAP THAT"

Drill and tap existing gas line holes (to 12 gram pierce and to valve) drill new valve transfer hole 90* from existing (as mentioned previously)

Drill and tap gas line block to accept 1/4"-28 threads and screw in CCI style pierce pin.

One issue would be drilling/tapping all those holes. Would be impossible to reverse to original design.

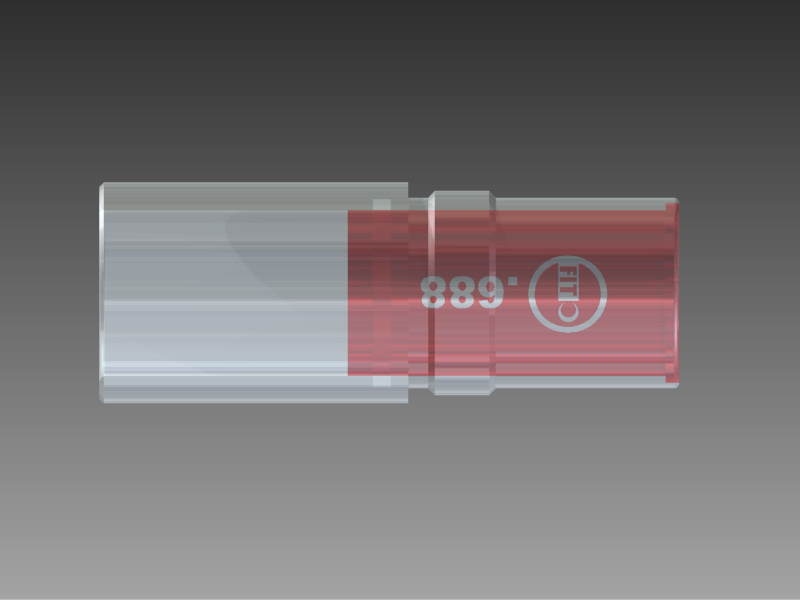

Picture shows new regulator body with tapped and plugged holes (I inserted M6 set screws but any thread would work) and CCI pierce pin

[/URL]

OPTION 2 "ALL NATURAL"

Drill and tap existing gas line holes (to 12 gram pierce and to valve) drill new valve transfer hole 90* from existing (as mentioned previously)

Use existing remote line air fitting and tap that for 1/4"-28 threads if the existing threads are different.

One issue would be clearance on the remote line adapter body to the regulator body.

A second issue would be if the old threads can be drilled out and retapped if needed or if the body would become too thin.

Here's the body for reference, note the distance of the banjo bolt from the end.

Also, what does everyone think about using TECHT iFIT inserts as a Freak-style insert? I know it's been done before my multiple sources (fatkid, super_stanchy) and would work pretty well I think.

We could probably even use the existing TPX barrel kit or do a custom barrel (idea shown below with no drawn threads; keeping the stock A-5 would work better than changing them)

Last edited by skibbo; 06-29-2013 at 05:12 PM.

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly

Maybe for the 12 gram and related lets find a standard one, like for a Phantom, and make it fit in the grip?

A fully contained 12 gram changer seems like a smart move.