i'm just spitballing here...

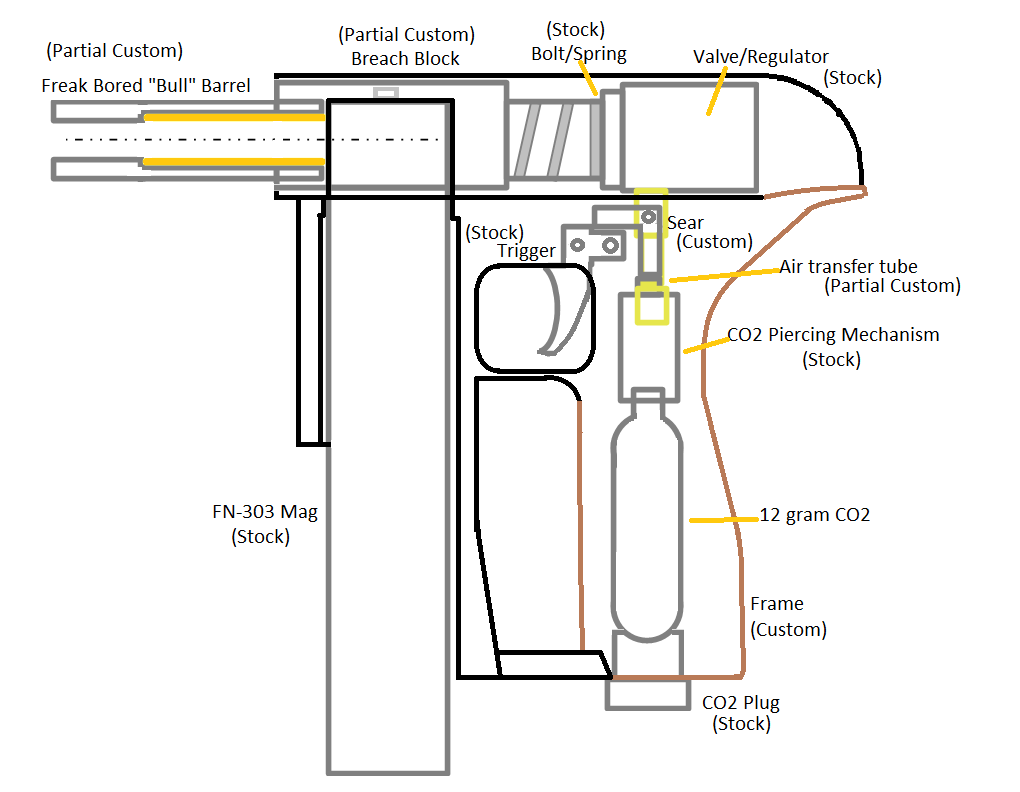

taking the pic of the TPX, and the photochop, the consensus of having the 12gram in the grip(or maybe 2?, or even a better reg to handle the increases for efficiency or flow) and retaining the TPX bolt system, how about taking the co2 piercing mechanism and totally removing the brass looking line, and rotating it 90* to the vertical so that its now in the grip. you can attach the peirce mechanism right in front of the TPX reg, giving the necessary area for the rotatory mag, getting the shortest, squat little gun since the M1942 Liberator...

now, is the trigger of a TPX mechanical? is there a way move it along so that the ergonomics could be better?

also, not knowing the FN303 or the mag, what about having the barrel, instead of the "whoosh" or a stub, you work an ugly 6+" freak bored barrel. a Tip 98 barrel but freak'd, for example. it would give better life to all those unused .690+ inserts AND would give better life for shooting regular paint out of it. plus, i love seeing tiny little guns with huge barrels, like in Johnny Dangerously, "its a 88Magnum. I use it to shoot though schools."

Reply With Quote

Reply With Quote