If we go with senario dreams tboard we could go smaller... or a no board semi only dumb electro

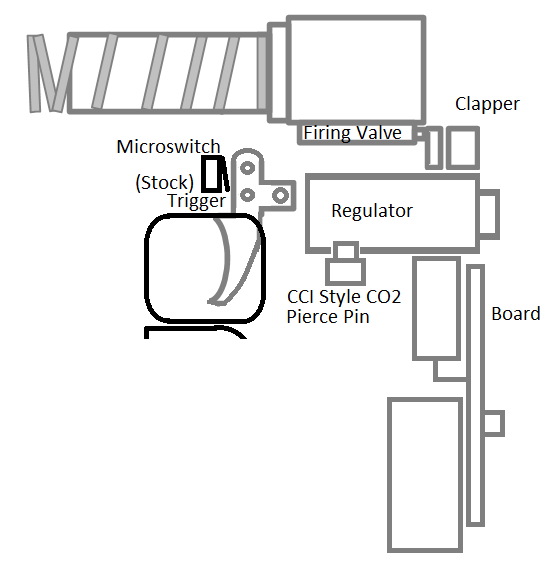

I woke up this morning and had an idea. If we could source a small diameter clapper style solenoid and board (like below but smaller 'solenoid' and non attached microswitch)

There would be an option to have burst/capped full auto. Wouldn't necessarily be needed with only 15 rounds but I think it would be fun. The clapper would go right behind the firing valve (if there's room, I'm not 100% on it's placement) with just a simple microswitch wired to the board. The grip frame should have enough room for everything plus a 9V battery.

Honestly, you wouldn't need anything complicated on the board either. Could just cap everything out of the box at 5-10 bps (10 would be overkill for a pistol w/15 rounds but oh well) and have semi, 3 round burst, and maybe full auto (although with the small mag size it'd be done in a second in a half capped at 10).

I figure it'd be awesome to be running around with one on burst. To my knowledge it would be the only mag fed pistol that would be able to do this.

I also see no reason why the regulator couldn't be moved to another position in the grip, possibly even vertically if needed. We'd have to figure out the pierce pin then (couldn't be tapped straight in, but there's options)

I'll re-draw a better picture of the clapper after work but there's the basic idea:

Team Akkadian Paintball Squad

B.S. Mechanical Engineering UW-Platteville 2012

Originally Posted by neftaly

If we go with senario dreams tboard we could go smaller... or a no board semi only dumb electro

So many awesome posts! Where to begin... one post at a time I guess.

Make it cocker threads and allow anyone to put whatever they like on it. The front will need to be longer, but we can deal with that.

If we use TiPX parts and make it clam shell then we can machine or print the shell halves. This is easier because it's how the TiPX parts were designed to be used.

Same problem I run into.Even worse when I am just one person currently!

Agree. We don't need the pull to activate the 12g feature. Just have a screw in knob to pierce it and be happy.

I love the way it took the AR furniture.I got to try out George's over here in NJ and it was very cool!